Superfinishing and Grinding Machines

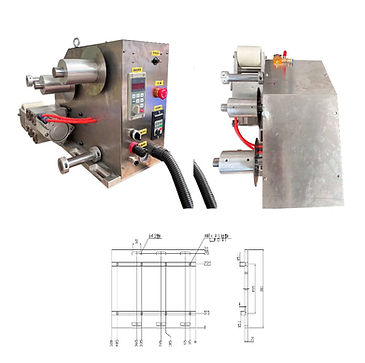

Our company is proud to introduce a revolutionary finishing polishing machine that surpasses 3M Company's Micro finishing polishing machine in the United States. Our machine utilizes a swing motion system with 4 guide posts and 8 bearings, a significant improvement over 3M's 2 guide posts and 4 bearings. This innovative system effectively reduces roller surface appearance after polishing , resulting in a smoother and more polished finish.

Furthermore, our machine features a magnetic brake, traditional mechanical brake, and eccentric bearing for movement, eliminating noise issues typically associated with traditional polishing machines. The pneumatic pop-up is equipped with a 3-axis flange telescopic movement system to ensure stability during use, reducing the need for rework. Our finishing polishing machine is perfect for achieving high-quality finishes with minimal noise and rework, making it an ideal choice for businesses seeking to enhance their polishing processes and increase efficiency.

With its advanced design and innovative features, our super-finishing machine is a game-changer in the industry. Equipped with a cutting-edge swing motion system, it guarantees a flawless finish, while its noise-reducing features make it suitable for any workspace. Additionally, the machine's pneumatic pop-up provides maximum stability and minimizes the need for rework, saving time and resources.

In conclusion, our super-finishing machine is the ultimate solution for businesses looking to improve their polishing processes and achieve high-quality finishes. Its advanced features and innovative design make it the ideal choice for any workspace requiring a reliable and efficient polishing machine . With our machine , you can achieve superior results with minimal noise and rework, making it a valuable investment for any business.

Superfinishing and grinding machines are used in various industries for different applications.

-

Centerless grinder: This machine is used for grinding cylindrical parts. The workpiece is placed on a work rest and then moved between a grinding wheel and a regulating wheel. The workpiece is supported by a blade, and the grinding wheel and regulating wheel move towards it to grind it.

-

Cylindrical grinder: This machine is used for grinding cylindrical parts. The workpiece is held in a chuck or collet and rotated while a grinding wheel grinds it.

-

Surface grinder: This machine is used for grinding flat surfaces. The workpiece is placed on a magnetic chuck and moved back and forth under a grinding wheel.

-

Tool and cutter grinder: This machine is used for sharpening cutting tools such as drill bits, milling cutters, and lathe tools. It uses a rotating grinding wheel to sharpen the cutting edge of the tool.

-

Belt sander: This machine is used for finishing flat or curved surfaces. It uses a sanding belt that moves continuously over the workpiece to remove material and create a smooth finish.

-

Polisher: This machine is used for polishing metal parts. It uses a rotating cloth or felt wheel to remove small imperfections and create a high-luster finish.

-

Lapping machine: This machine is used for precision grinding and polishing flat surfaces. It uses a rotating lap plate and a grinding fluid to remove material and create a flat, smooth surface.

-

Honing machine: This machine is used for finishing cylindrical surfaces. It uses a honing stone that moves in a circular motion to remove material and create a smooth surface.

-

Superfinishing machine: This machine is used for producing a superfinish on metal parts. It uses a rotating cloth or felt wheel to remove small imperfections and create a mirror-like finish.

-

Grinding and polishing machines: These machines are used for grinding and polishing metal parts. They use a combination of grinding wheels and polishing wheels to remove material and create a high-luster finish.

These are just a few examples of superfinishing and grinding machines. There are many other types of machines available, each with its own specific application and function. The choice of machine depends on the type of workpiece, the desired finish, and the production requirements.